|

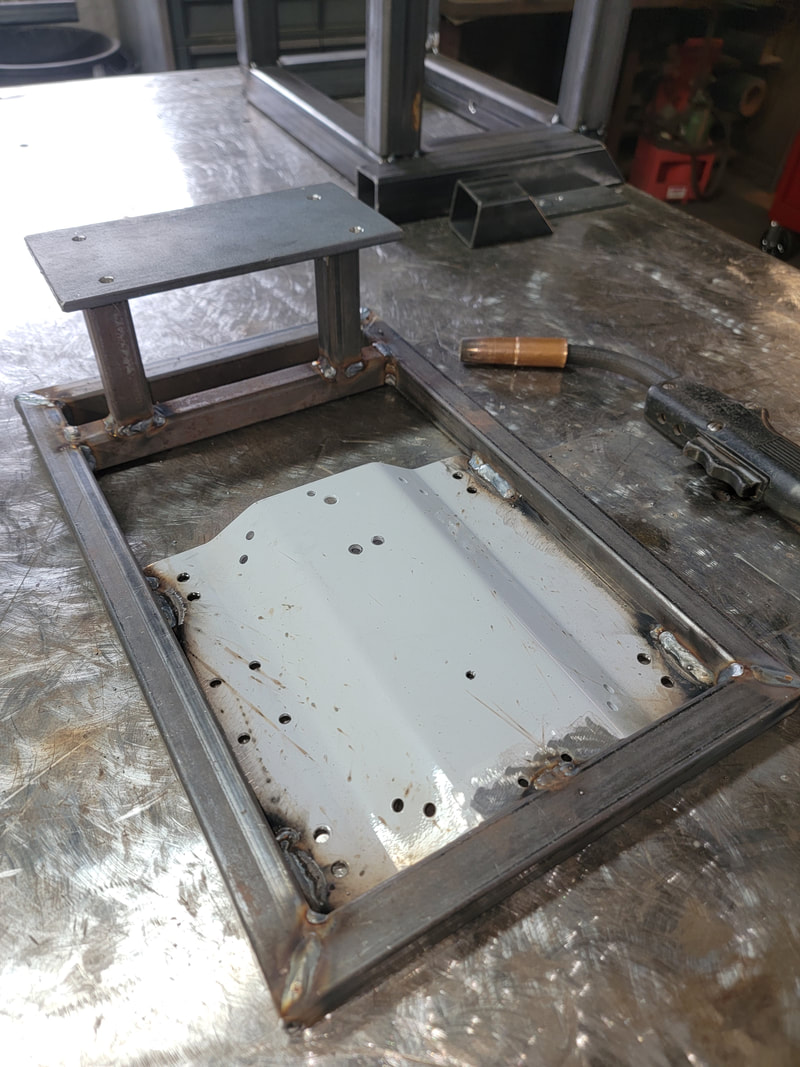

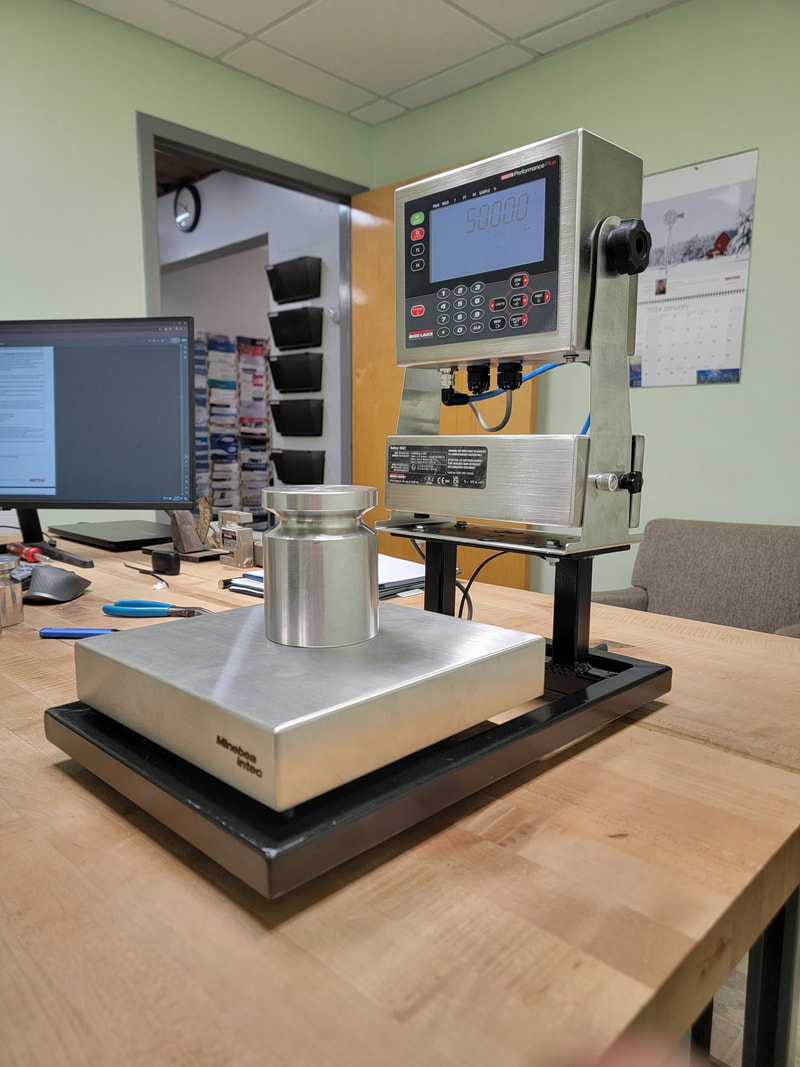

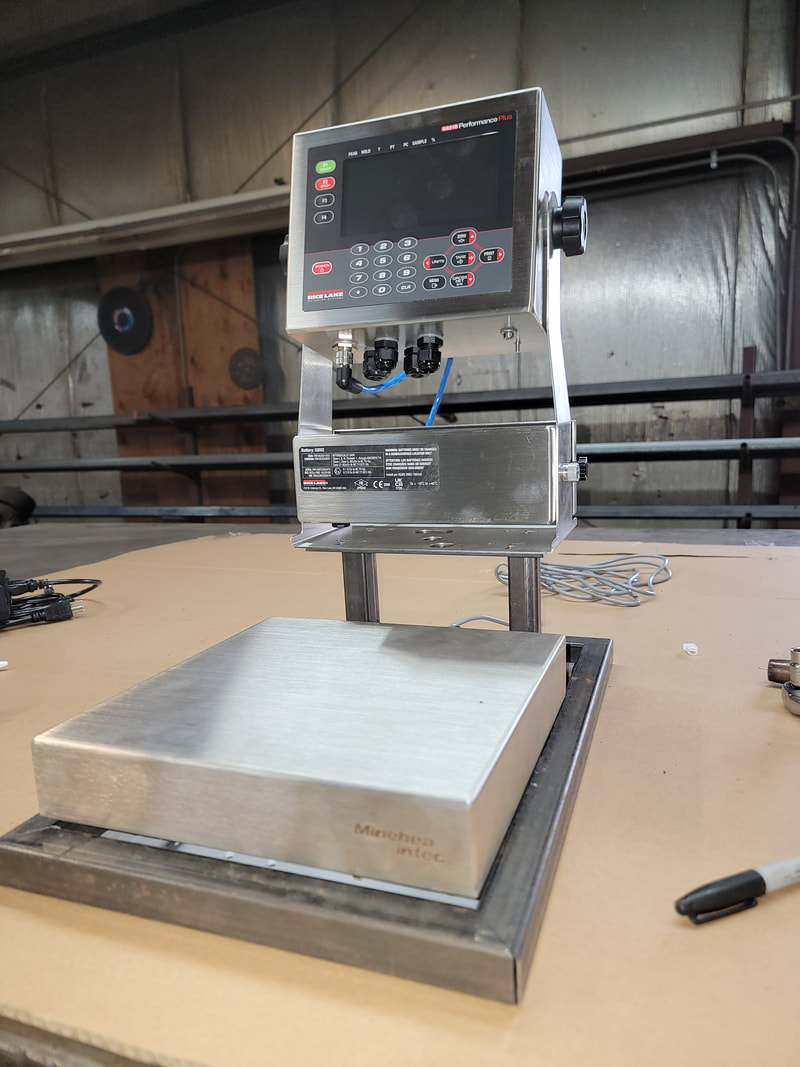

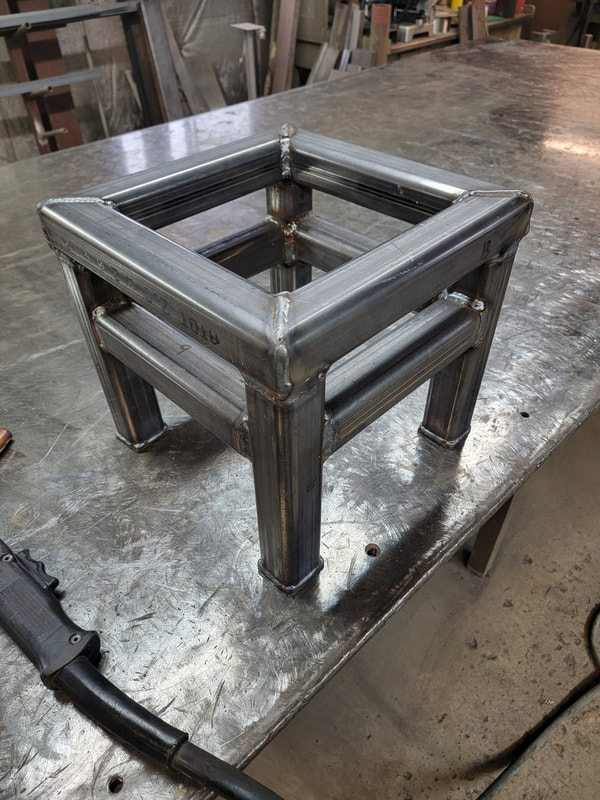

The Koehler Scale fabrication shop has been busy building some works of art. Heavy duty stands and columns can increase the reliability of any scale by keeping all the scale components mounted and protected. The cable that runs from the scale base to the indicator is one of the most common failures we come across. Routing the cable through the column to limits its exposure to harsh environments and keeps it well protected.

0 Comments

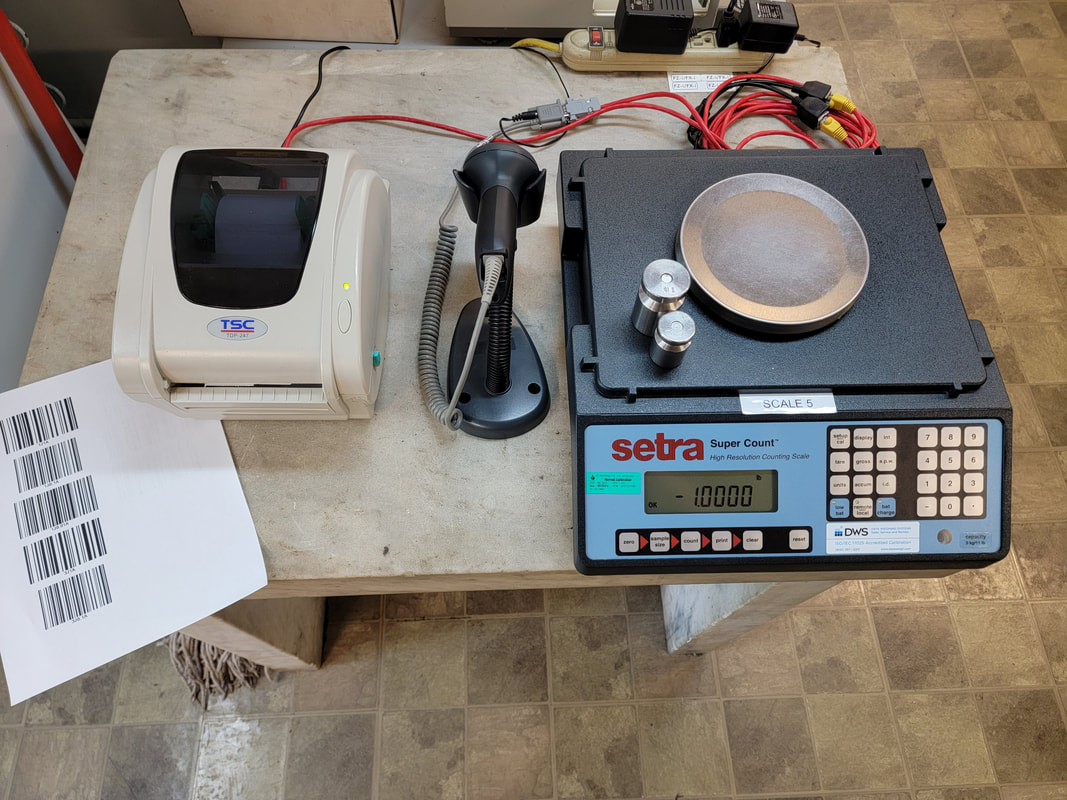

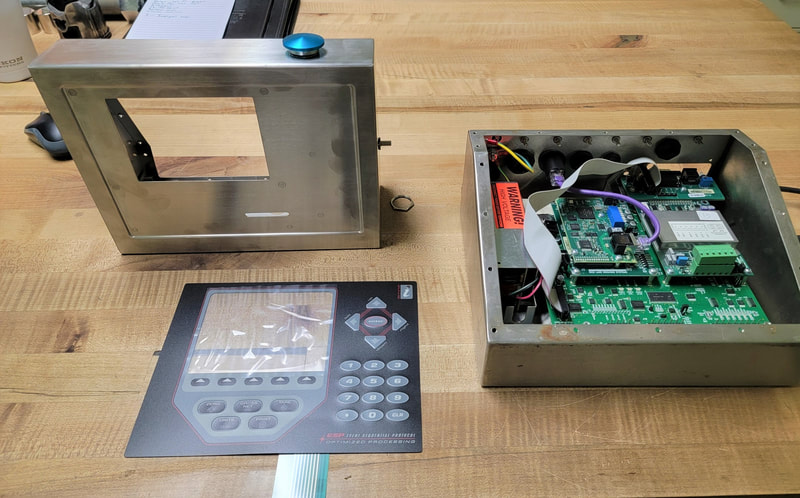

A customer was interested in using additional features of their industry standard Setra Super count scales. After some struggles they contacted Koehler Scale for assistance. These scales are used for inventory purposes, precisely counting pieces of similar mass. When switching to count a different part, the scale needs to be setup properly for that part. The customer only has a finite amount of parts and the average piece weight of all the parts they are counting are all known. To speed up the process the customer would like to scan a barcode with average piece weight encoded and go straight to counting. This will potentially save several minutes every changeover and prevent setup errors. This setup has a printer and a linear imager sharing 1 bi-directional rs232 port utilizing a cable we custom made to adapt the RJ45 port on the Setra to the common DB9 that most serial devices utilize. After some research we learned this can be accomplished by only using the serial transmit (Tx) from the linear imager and serial receive on printer going to the same port on the Setra. This will prevent serial data from being sent to the scanner and it will prevent the linear imager from sending serial data to the printer and everything will exist harmoniously.

A customer was in a pinch and needed their race car scale calibrated after some repairs were done to prepare for the next race. We were the only one locally able to respond to the call in a timely manner so we got the business. The customer is racing the NTT Indy Car series which is among the highest levels of racing. Very cool to see what some scales are used for out there in the world. Good luck at Road America this weekend Dale Coyne Racing!

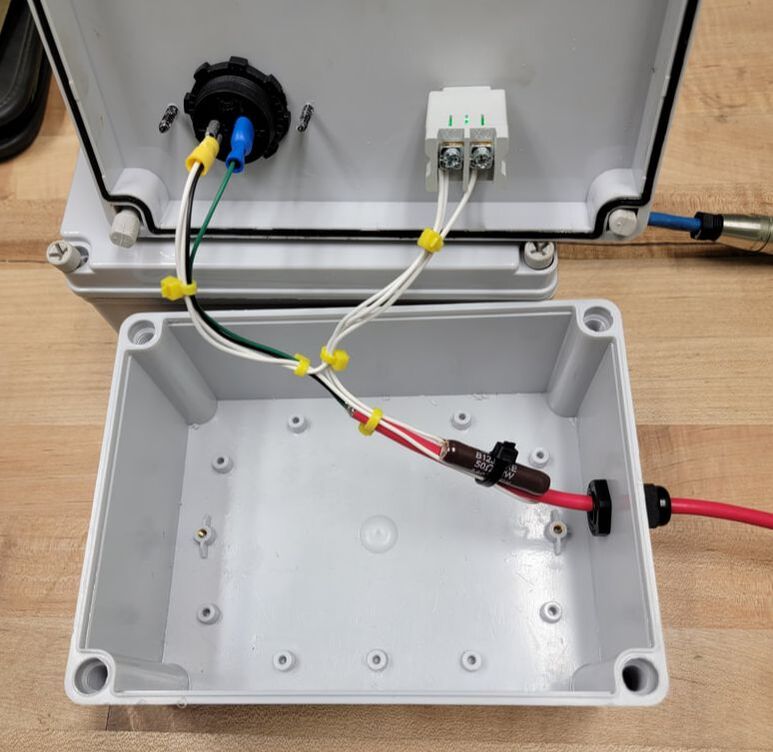

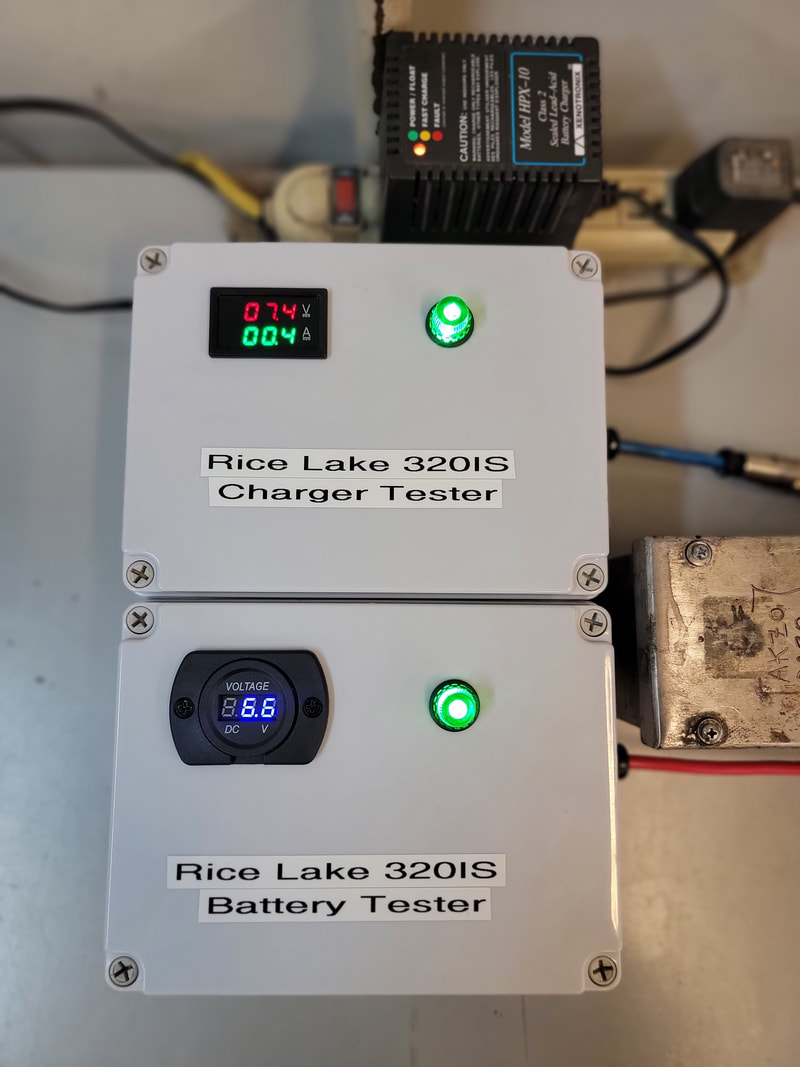

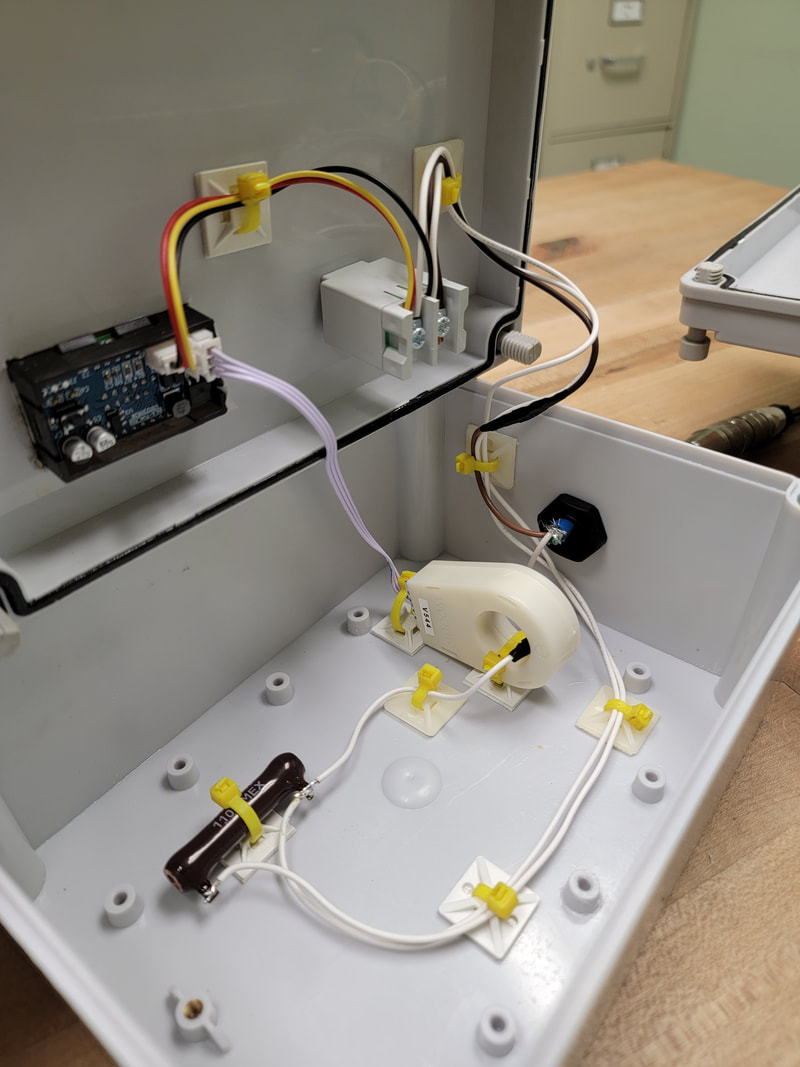

Some problems require custom solutions. One of our customers has a fleet of intrinsically safe instrumentation all of which use rechargeable batteries. Intrinsically safe batteries come equipped with an intrinsically safe barrier which limits the electrical current to a level unable to create a spark. This type of equipment is necessary in places that deal with flammable materials and this level of safety earns the name "explosion proof" We designed and built a custom tester for both the charger and battery so the customer can easily do some troubleshooting on their own. When you have 50+ batteries and dozens of charging stations it can become a handful to make sure everything is functioning properly. Now they just have to hook up a battery or charger to the tester and a green light will illuminate if it tests "good."

KSI Just wrapped up another custom project. From clearly identifying a customer's needs to creating a turnkey solution contact us today to solve all your business' weighing problems!

This scale is made to piece count fasteners as they are being packaged. Once the desired quantity is packed by the operator a button is pressed triggering a digital input on the scale. There is a custom program written for this particular scale so it can calculate the pieces packed per hour. With this setup operator run rates can be recorded and data can be analyzed for further process improvement. A very productive day was had installing 8 Sartorius load cells on two tanks. Always a treat to work in a brand new building on brand new equipment.

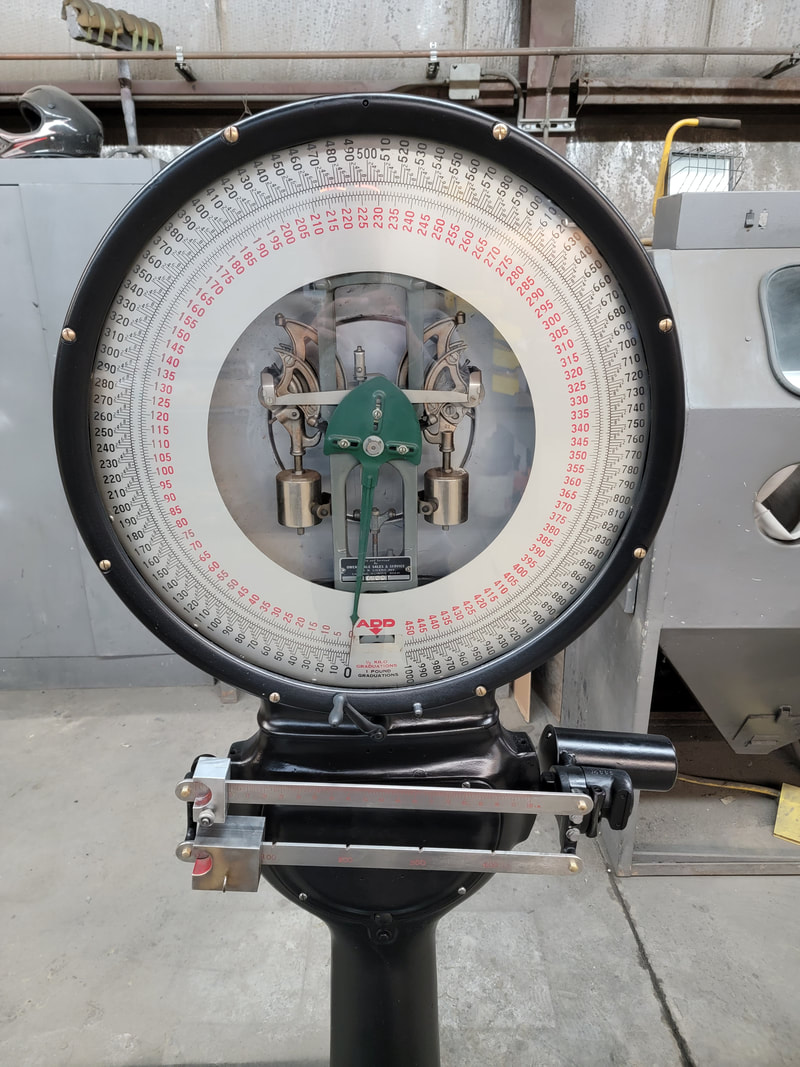

A long time customer contracted us to overhaul the first scale the company ever had. They planned to place it on display in their lobby. It had been out of commission for quite some time and in need of some serious repairs. A cracked casting was the main issue to be corrected. After the crack was ground out and welded we inspected, repaired and adjusted all the mechanical components of this fine example of a vintage Toledo Honest Weigh dial scale. We threw a fresh coat of paint and did several final adjustments to bring this scale back into tolerance. This functional piece of history will look great in any space. This scale was designed over 100 years ago and this unit was likely manufactured over 80 years ago. When working properly will perform as well as any modern digital scale.

The dream team wrapped up another custom project. This standard platform was modified in the shop to be a portable drum filling scale. We fabricated a column to mount the digital weight indicator, forklift channels allowing the scale to be safely lifted with a forklift and a pallet turn table so the pallet can be rotated on the scale. As always we try to build simplicity and durability into all our projects. This scale will be accurately filling drums for many years to come..

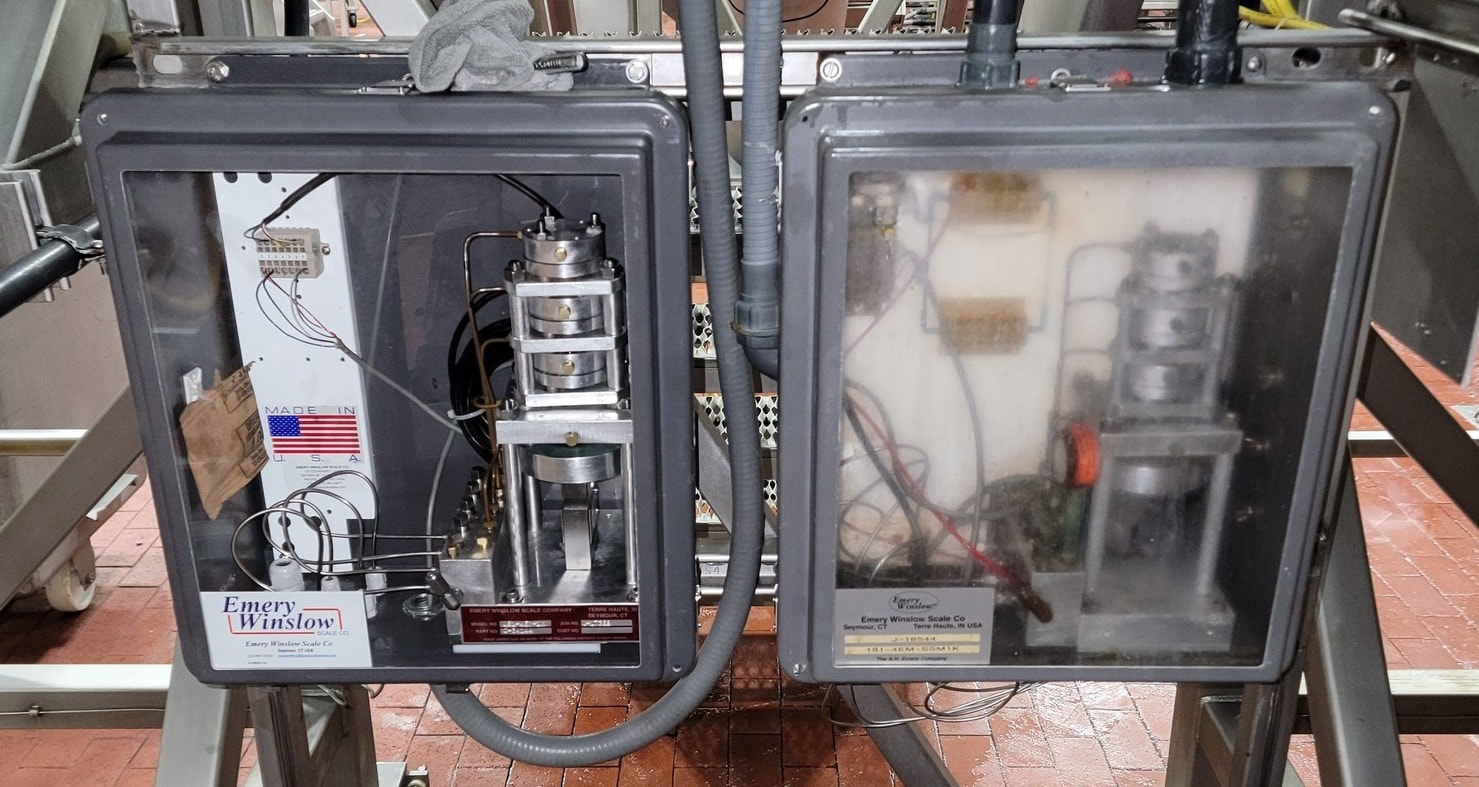

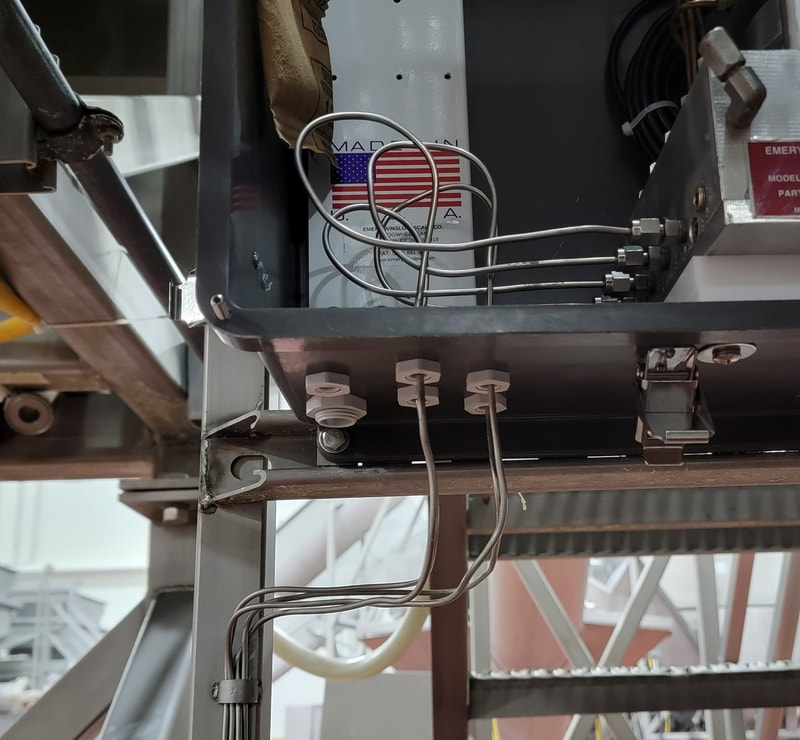

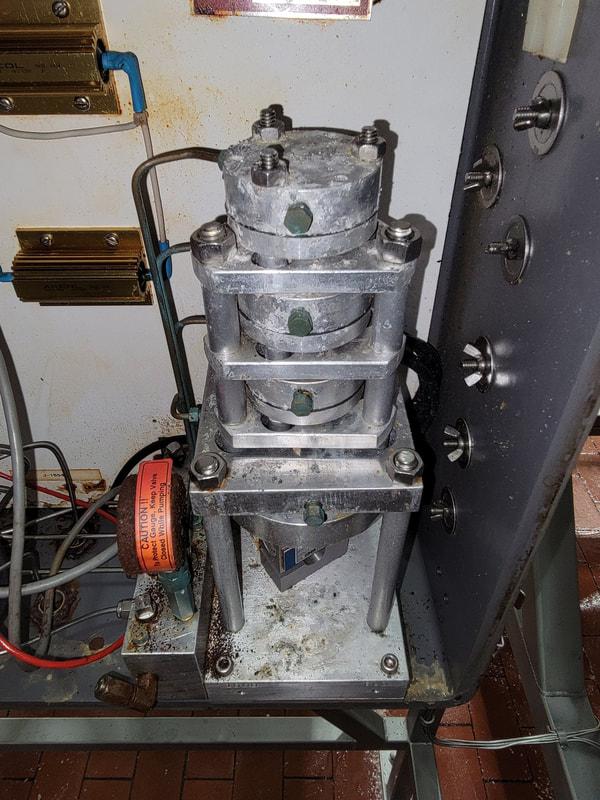

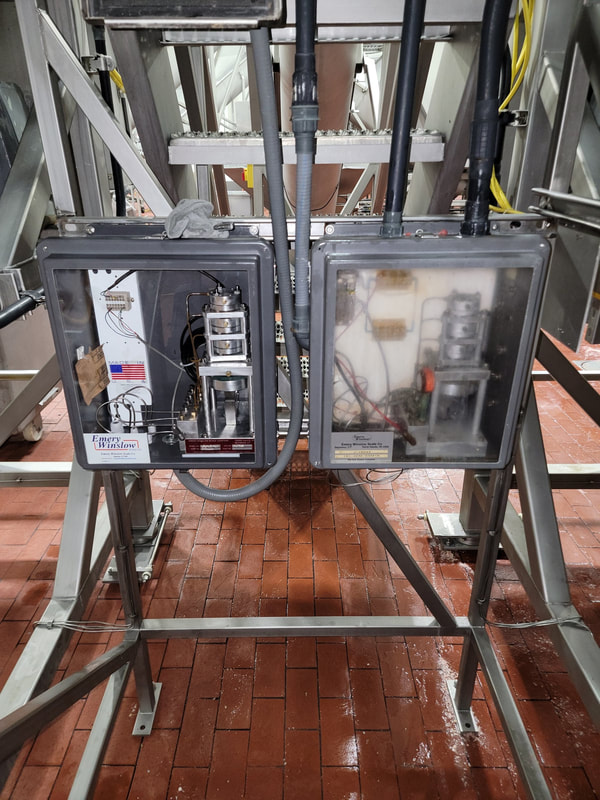

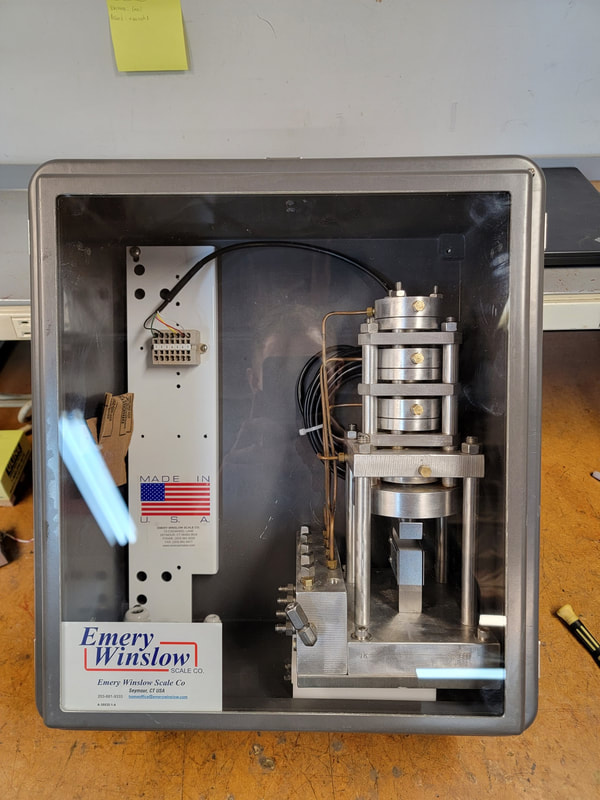

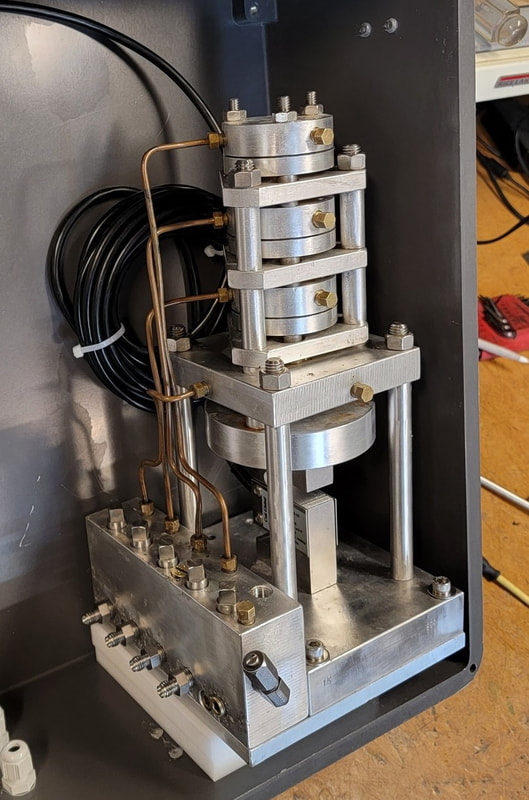

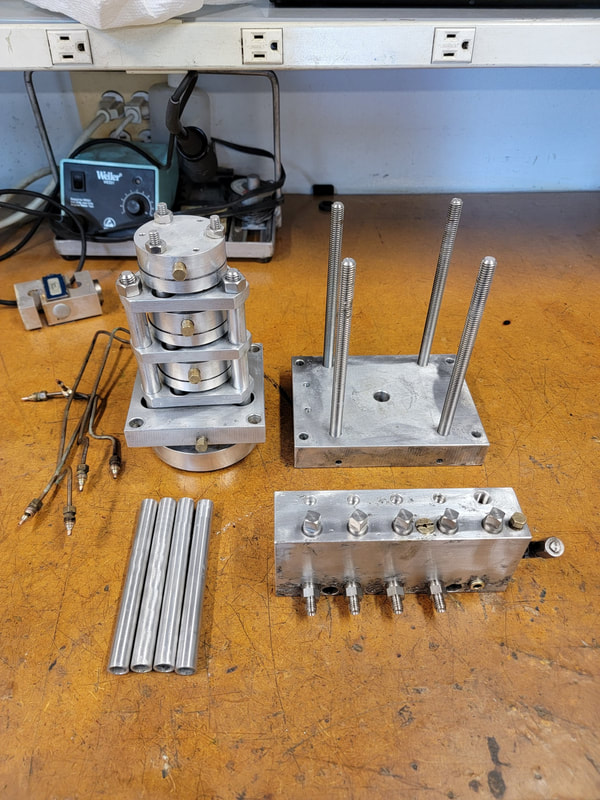

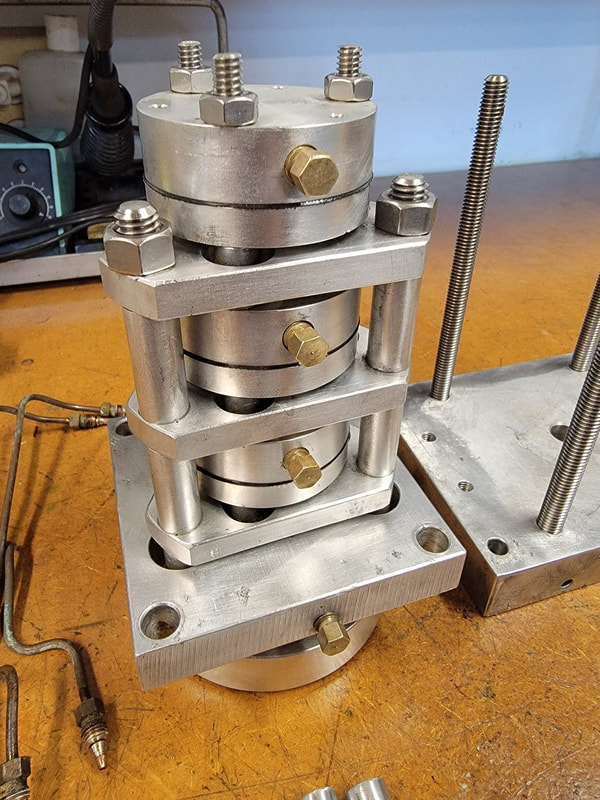

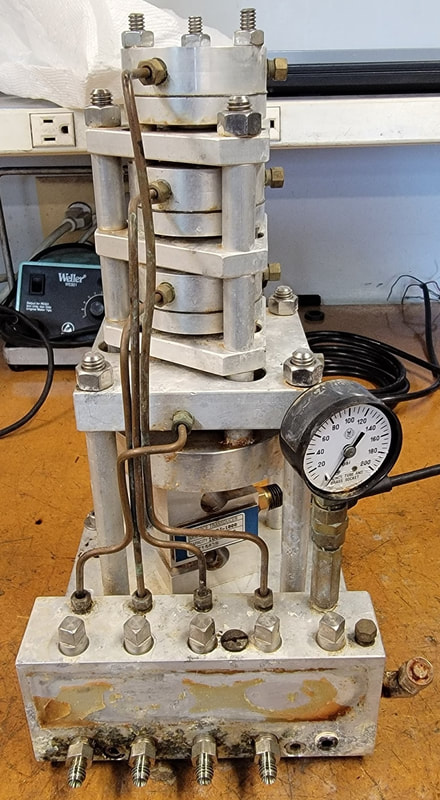

It makes our job mega enjoyable when we get to work on cool projects like this! Installation of the overhauled totalizer went super smooth and we didn't even break a sweat!! We were working in a refrigerator... Each foot of this massive blender sits on top of a hydraulic load cell, literally suspended by hydrostatic fluid pressure. Each of these hydraulic load cells is plumbed into the totalizer where the forces are mechanically summated and transferred to the force transducer. This transfer of force from the piston in the load cell to the piston in the totalizer cell functions the same way the brakes do on your car. The force transducer is just a standard strain gauge load cell and it is wired into to a digital weight indicator for simple weight readings. The customer goes one step further with automation and they utilize the analog output of the weight indicator to send weight information to their Allen-Bradley PLC system that does all the controls for this blender. Several ingredients can be automatically be add by weight with this setup removing any possibility of operation error.

The heart of any hydraulic load cell system is the totalizer. After 20 plus years of use, the force transducer in the totalizer stack failed and the unit was in need of some tender loving care. We partially dissembled the stack to clean off any corrosion and residue while inspecting all moving parts. A brand new force transducer was installed and the stack was reassembled and mounted in the enclosure just in time to be installed in the A.M.! It's always a treat to be trusted to work on equipment like this.

|

Mike ZegarMike is the Co-Owner of Koehler scale Archives

April 2024

Categories |

RSS Feed

RSS Feed